So basically fried my 4 in 1 esc twice now and i'm over having to replace the whole thing when it dies so I want to switch to have 4 escs purely for the convenience but not too sure what bits I need (I'm very new to fpv). I have an Eachine wizard x220s. Am I right in thinking I need to replace the 4 in 1 esc with a power distribution board with the 4 escs as my flight controller does not have a built in pdb?

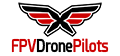

This is the current 4 in 1 esc

uk.banggood.com

uk.banggood.com

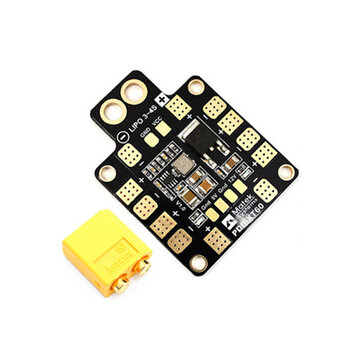

What escs I think I should replace it with (BLHeli_S and Dshot600 like the current 4 in 1)

www.banggood.com

www.banggood.com

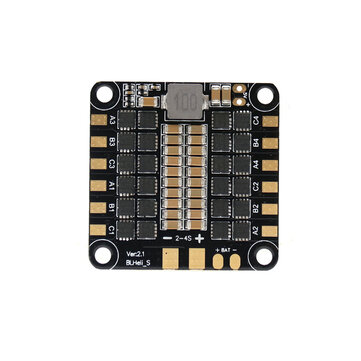

Not sure what pdb maybe this one?

uk.banggood.com

uk.banggood.com

Any help would be greatly appreciated : )

This is the current 4 in 1 esc

Eachine Wizard X220S FPV Racer RC Drone Spare Part 4 in 1 30A ESC BLHeli_S 2-5S Dshot600

Only US$59.99, buy best Eachine Wizard X220S FPV Racer Spare Part 4 in 1 30A ESC BLHeli_S 2-5S Dshot600 sale online store at wholesale price.

What escs I think I should replace it with (BLHeli_S and Dshot600 like the current 4 in 1)

HGLRC 30A 30AMP 2-5S BLHeli_S 16.5 BB2 Brushless ESC Dshot600 Ready for RC Drone FPV Racing

Only US$11.39. Get the HGLRC 30A 30AMP 2-5S BLHeli_S 16.5 BB2 Brushless ESC, Dshot600 ready for RC drone FPV racing. High-quality and reliable, this ESC is perfect for enthusiasts.

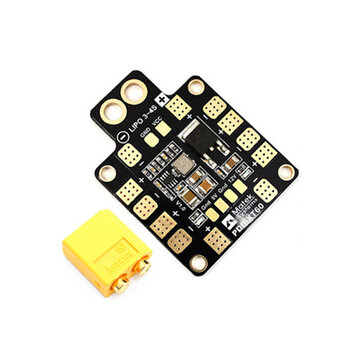

Not sure what pdb maybe this one?

Matek Systems PDB-XT60 W/ BEC 5V & 12V 2oz Copper for RC Drone FPV Racing Multi Rotor

Only US$5.64, buy best Matek Systems PDB-XT60 W/ BEC 5V & 12V 2oz Copper For RC Multirotors sale online store at wholesale price.

Any help would be greatly appreciated : )